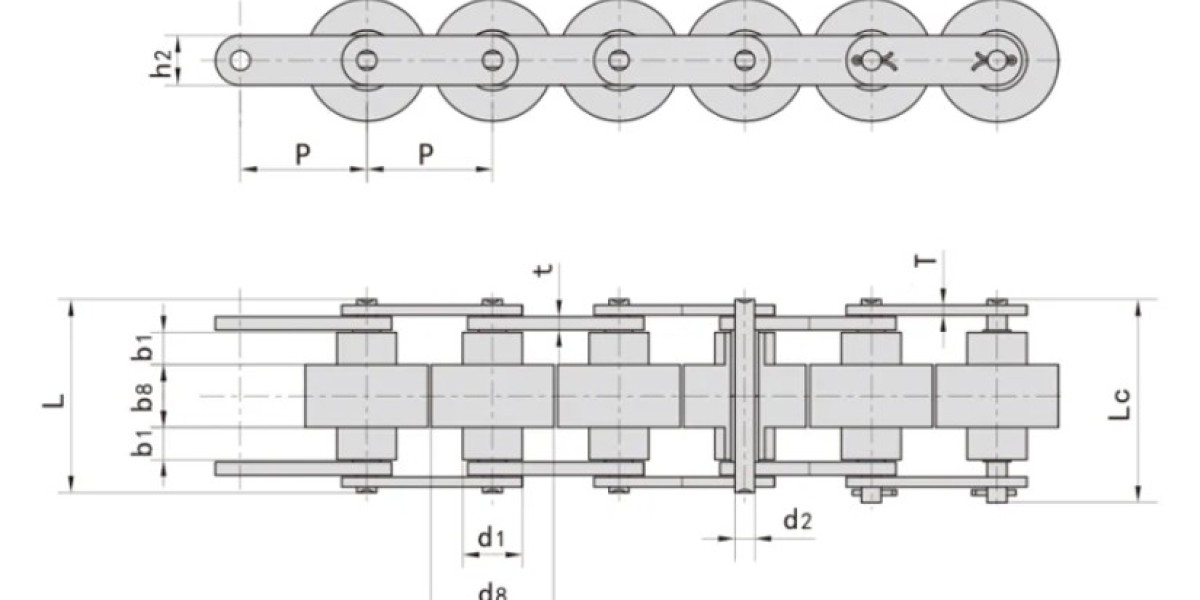

In a variety of styles of industrial production transmission chains, Heavy duty series type roller chains is more common, but also because of its application often cause Heavy duty series type roller chains will often be damaged. The damage of Heavy duty series type roller chains is caused by its tired application, and the result is that the transmission chain will be ineffective and harm the work efficiency.

When the Heavy duty series type roller chains are damaged, the transmission chain can be reversed and applied again with the slightly damaged side. In order to reduce its damage, Heavy duty series type roller chains can be lubricated quarterly. Together, to prevent the long-term application of the transmission chain, it can also greatly reduce the damage.

Due to the long-term application of Heavy duty series type roller chains, it will not only lead to too much damage, but also make it loose and even dislocation. In order to prevent the damage and dislocation of the transmission chain, the tension of the transmission chain should be improved, and in the final analysis, it is to buy a good quality Heavy duty series type roller chains, which can improve the production and processing precision of the transmission gear and the strength of the driving face.

Perhaps people should pay more attention to the Heavy duty series type roller chains at that time, it should be installed parallel with the transmission chain shaft, and properly check, so that it can reasonably reduce the damage of the transmission chain, otherwise it will be low transmission chain and transmission chain shaft offset, more heavy transmission chain damage.

Chain plate conveyor is composed of motor, rotating shaft, barrel, tightening equipment, sprocket chain, transmission chain, lubricating fluid, transmission chain and so on. Is the key raw material transportation and loading and unloading handling machinery and equipment, then the most critical to promote this raw material there are two parts, the transmission chain, the use of the transmission chain circulation system back and forth fitness exercise to show the traction belt driving force. Second, metal sheet, which is used as a carrier in the whole process of transporting raw materials. The basic principle of the chain conveyor is to use these two effects to push the raw materials along with the level or skew direction transport. Chain conveyors can be thoroughly integrated in various fields, such as power engineering, wine making, chemical plants, diagnosis and treatment, food, machinery and equipment. And strive to achieve the requirements of each manufacturing industry, the chain plate conveyor has a variety of specifications and specifications, and can carry out practical design ideas for the belt conveyor to exceed the regulations and goals.

In order to improve the tightness of Heavy duty series type roller chains, the screws can be changed from 2 to 4, which will make the actual operation more lightweight, and improve the safety level of the actual operation of the transmission chain, and promote the operation of the transmission chain more stable, and its own use period can also be increased.

Heavy duty series type roller chains https://www.qj-chain.com/Heavy-duty-series-type-roller-chains.html